Introduction

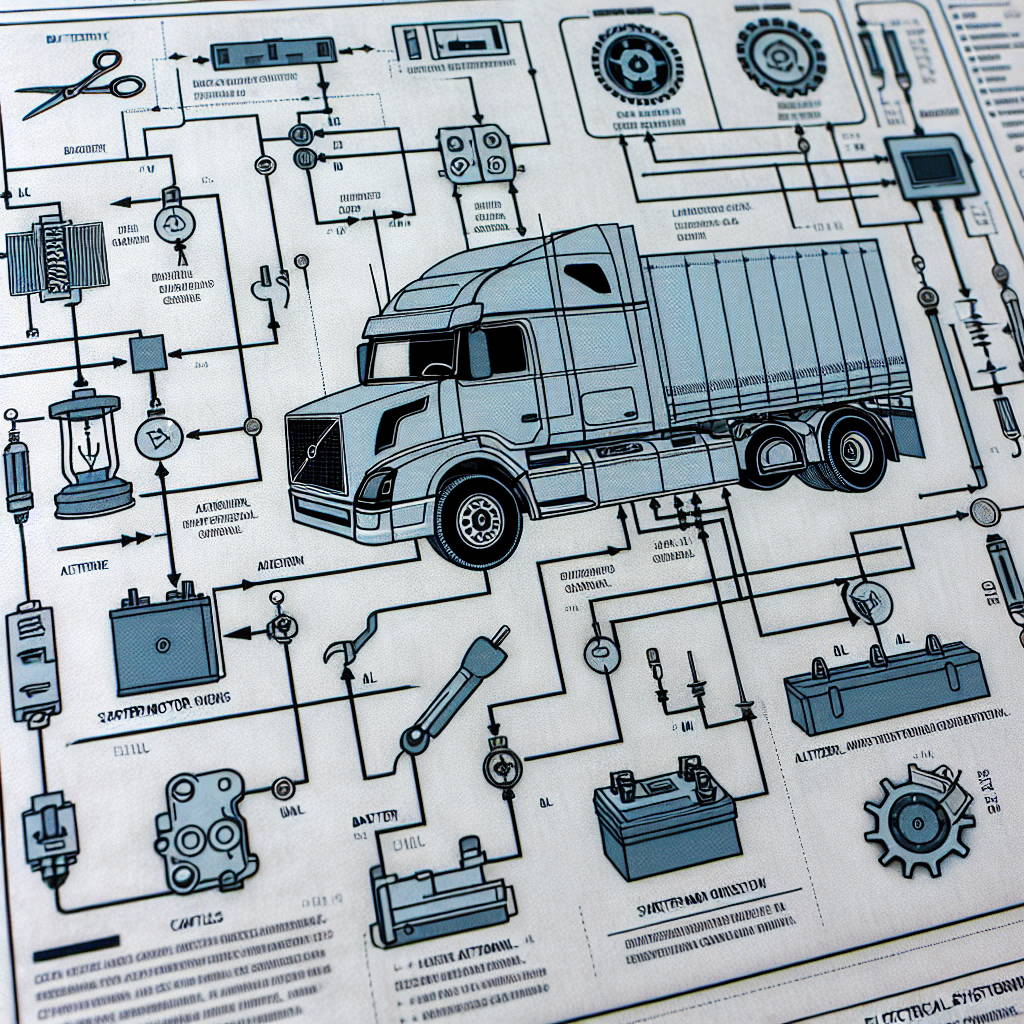

Dealing with electrical issues in your Volvo VNL can be both challenging and frustrating. Whether it’s a persistent battery drain, faulty wires, or constantly blown fuses, understanding how to troubleshoot these problems can save you both time and money. This guide provides detailed solutions to the most common electrical issues and offers preventative measures to keep your truck's electrical system running smoothly.

Common Issues

- Battery Drain

- Faulty Wires

- Blown Fuses

Step-by-Step Solutions

Battery Drain

- Check Lights:

- Ensure no interior or exterior lights are left on.

- Inspect Battery Terminals:

- Look for corrosion or loose connections. Clean and tighten as necessary.

- Test for Parasitic Draws:

- Use a multimeter to check for parasitic draws. Disconnect the negative battery cable and place the multimeter in series between the cable and battery terminal. If there's a draw, start pulling fuses one by one to identify the circuit causing the issue.

- Battery and Charging System Health:

- If no parasitic draw is found, have the battery tested for health and the charging system checked for proper functioning.

Faulty Wires

- Visual Inspection:

- Examine all wiring harnesses for signs of fraying, wear, or damage. Pay close attention to areas where the wiring can be pinched or chafed, such as near moving parts or at connection points.

- Check Continuity:

- Use a multimeter to check for continuity in the wires related to the malfunctioning system. This can help identify broken or shorted wires.

- Repair or Replace:

- If faulty wires are found, repair or replace the affected sections with the proper gauge and type of wire. Secure wiring away from moving parts to avoid future damage.

Blown Fuses

- Identify and Consult Manual:

- Identify which fuse has blown and consult the vehicle manual to understand its purpose and circuit.

- Visual Inspection:

- Inspect the wiring and components associated with the blown fuse for any visible signs of damage or wear.

- Replace Fuse:

- Replace the blown fuse with one of the same amperage. If the fuse blows again immediately, diagnose and repair using a multimeter and wiring diagram.

- Check Electrical Load:

- Ensure that the correct electrical load is being used on the circuit. Do not upgrade the fuse amperage as it can lead to more serious issues.

Preventative Measures

- Conduct regular vehicle inspections, checking for wear or damage on wiring harnesses and connections.

- Ensure all lights and electrical components are turned off when the vehicle is not in use to prevent battery drain.

- Maintain clean and tight battery connections to minimize the risk of corrosion and loose connections.

- Use the appropriate amperage fuses and avoid overloading circuits with excessive electrical load.

- Implement a schedule for testing and replacing batteries at regular intervals, as per the manufacturer's recommendations.

- Train vehicle operators on the proper use of electrical components to prevent inadvertent damage or strain on the system.

Expert Tips

- Battery Drain:

- Consider using a battery charger to ensure a full charge before identifying parasitic draws, as low battery voltage can affect test accuracy.

- Identifying Faulty Wires:

- Investing in a wire tracer tool can streamline the process, especially for complex wiring harnesses, by helping to locate breaks or short circuits.

- Replacing Blown Fuses:

- Use a multimeter set to measure resistance to check for short circuits in the circuit before installing the new fuse.

- Keep a Detailed Log:

- Keep a detailed log of all troubleshooting steps taken, including any parts replaced and test results. This can provide valuable information for future diagnostics.

- Consult a Certified Volvo Technician:

- For complex electrical issues, consider consulting with a certified Volvo technician or utilizing Volvo-specific diagnostic tools to ensure accurate diagnosis.

Case Studies

Case Study 1: Battery Drain Resolution

A Volvo VNL truck experienced persistent battery drain, leading to frequent jump starts. Following the troubleshooting guide, an experienced technician identified a parasitic draw from a malfunctioning GPS unit that was incorrectly wired. Isolating and correcting the wiring issue resolved the battery drain, preventing further incidents. The truck owner implemented regular electrical system checks as a preventative measure.

Case Study 2: Faulty Wires and Blown Fuses

In another instance, a fleet of Volvo VNL trucks reported various electrical malfunctions, including intermittent lighting failures and blown fuses. A team of technicians traced the issue to a common wiring harness section prone to chafing against the chassis, causing short circuits. By replacing the affected section and reinforcing it against future damage, the fleet experienced a significant reduction in electrical issues. They also implemented a quarterly check on all wiring harnesses as part of their maintenance routine.

Case Study 3: Systematic Testing and Resolution

A Volvo VNL truck repeatedly blew fuses for the trailer lights, presenting a challenge for both the driver and maintenance team. Using a systematic approach as outlined in the troubleshooting guide, the team identified a short circuit in the trailer wiring. They used a wire tracer tool to locate and replace the damaged section, ensuring proper isolation and protection against future wear. This experience led to the implementation of an annual trailer wiring inspection for the entire fleet.

FAQ

What should I do if my Volvo VNL experiences frequent battery drain?

Start by checking if any lights were left on, inspect the battery terminals, and test for parasitic draws using a multimeter. If the issue persists, have the battery and charging system tested for proper functioning.

How can I prevent electrical issues in my Volvo VNL?

Conduct regular vehicle inspections, maintain clean and tight battery connections, use appropriate amperage fuses, and train vehicle operators on the proper use of electrical components. Implement a schedule for battery testing and replacement as per the manufacturer's recommendations.

What tools are useful for diagnosing electrical issues in the Volvo VNL?

A multimeter, wire tracer tool, and the vehicle manual are essential tools for diagnosing electrical issues. For complex issues, consult with a certified Volvo technician or use Volvo-specific diagnostic tools.

Can upgrading the fuse amperage solve blown fuse issues?

No, upgrading the fuse amperage is not a solution and can lead to more serious issues. Always replace blown fuses with ones of the same amperage and diagnose the underlying issue causing the fuse to blow.